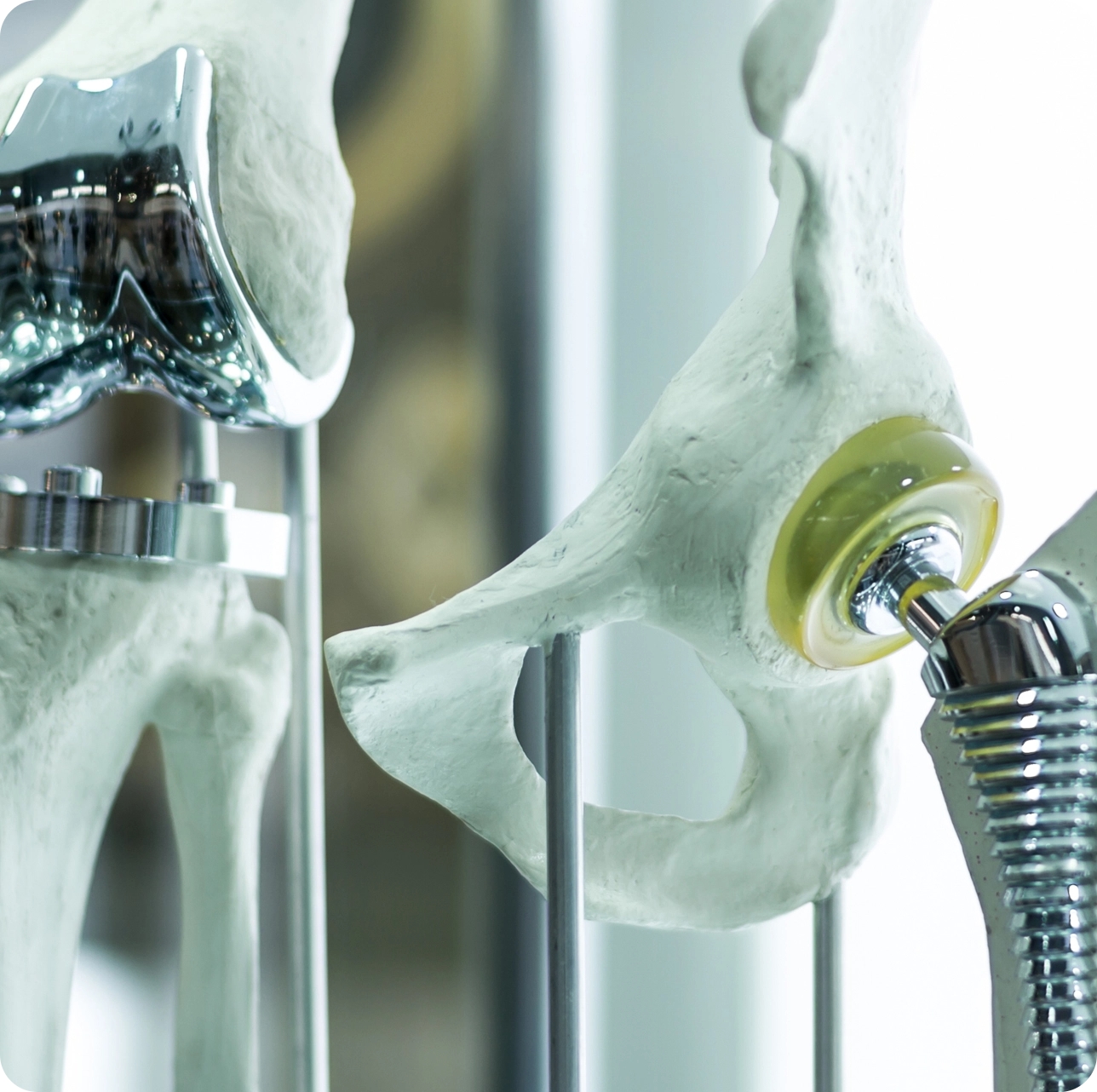

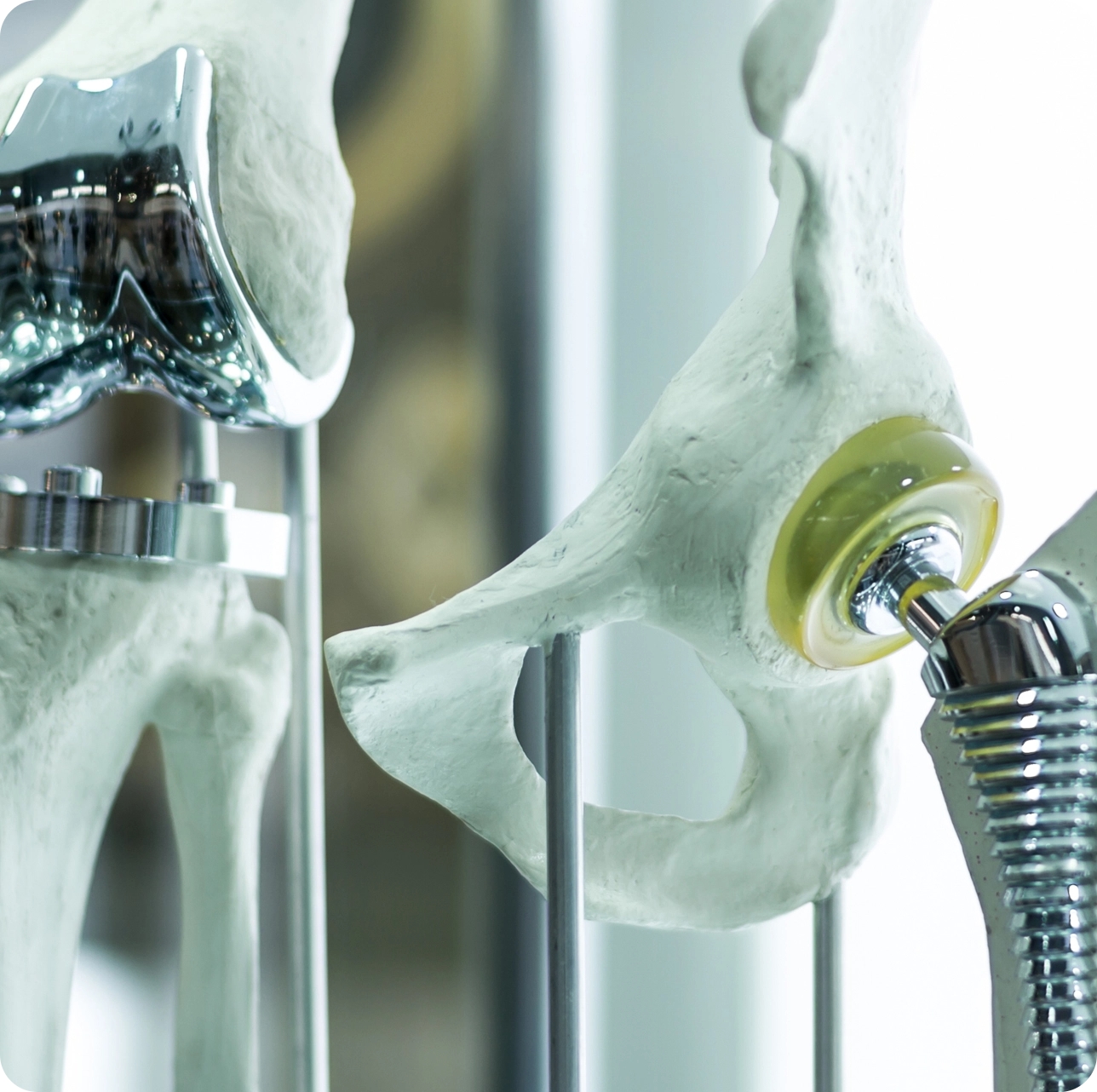

Biocompatibility

Exceptional biocompatibility of products destined for the biomedical sector thanks to the certified guarantee of neutral behaviour in the body of items with oxide coating.

The certainty of obtaining vivids colour and guaranteed durability, the treatment that enables titanium to deliver the best performance and aesthetics.

Wide range of colours can be obtained

Makes feature easy to identify

Clean passivated surface

Exceptional biocompatibility

Electrical insulation

Seizing eliminated

Feature's dimensions remain unchanged

Exceptional biocompatibility of products destined for the biomedical sector thanks to the certified guarantee of neutral behaviour in the body of items with oxide coating.

Elimination of seizing issues typical of titanium alloys. Precision masking can be used in each process according to individual requirements.

The conventional colour of titanium by anodic oxidation is achieved by immersing the item to be oxidised into an electrolyte solution and connecting it to the positive pole of a current generator. The exchange of current between metal and the solution results in the item being covered with a coloured oxide film, with the thickness varying from 200 to 900 nm in TYPE III oxidation.

Alticolor closely follows oxidation method specifications to achieve bright, intense colours.

It must be emphasised that the colours that appear on the surface of the titanium with anodic oxidation are not due to the presence of pigments, but rather the phenomenon of interference.

Treatment carried out in accordance with standards AMS 2488, DIN LN 9368-4 and DIN LN 9368-7

Thanks to specialist experience in treatments on titanium,

Alticolor can guarantee an extensive range of more than 20 colours,

which can be implemented through Type III anodising.

Since 1996, Alticolor has been the trusted point of reference for companies in need of treatments on titanium components.

Experience of more than twenty years enables Alticolor to support customers operating in different sectors, ranging from jewellers seeking alternative materials to gold through to known producers of titanium prosthetics requiring colour anodising on titanium to differentiate between component sizes.

Alticolor treatments undergo rigorous control procedures

resulting in certification to guarantee the quality

of the process management.

ISO 9001:2015

EN 9100:2018

13485:2021

45001:2023

14001:2015

Chemical

processing

NADCAP

Accreditation

LICENCE N° 768

LICENCE N° 768