We give

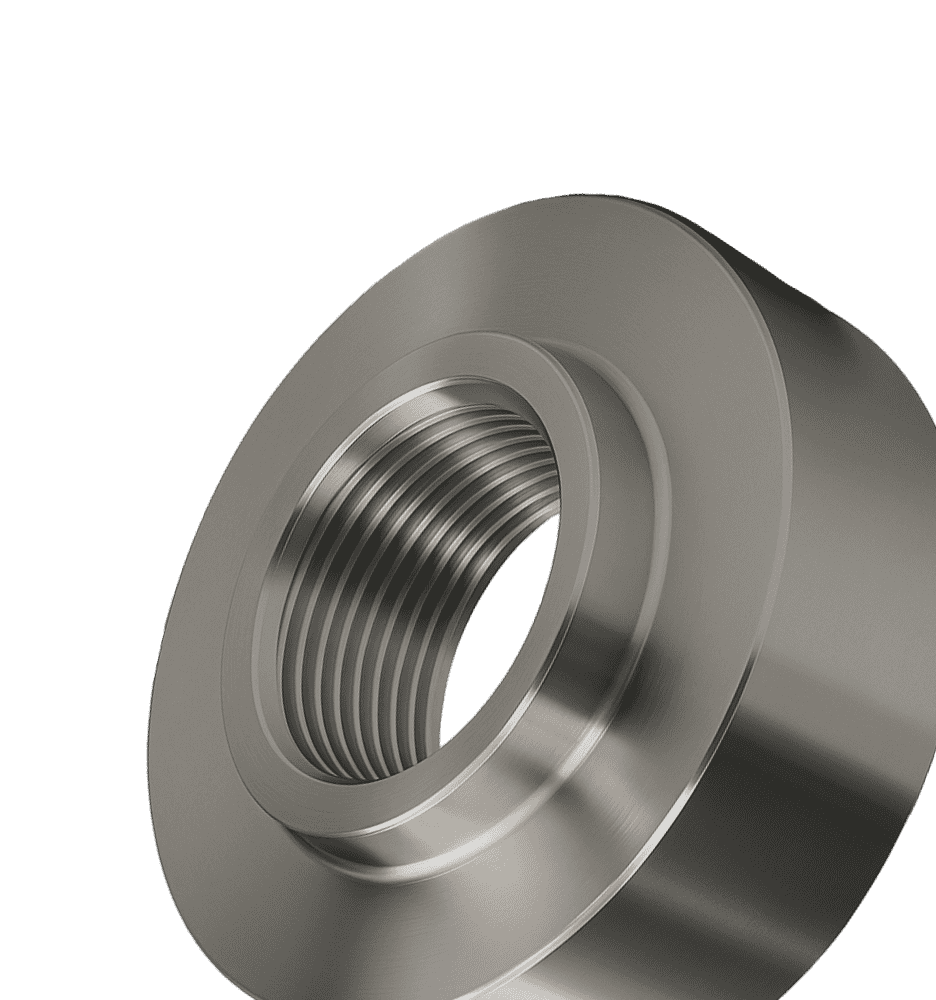

every metal

the best treatment

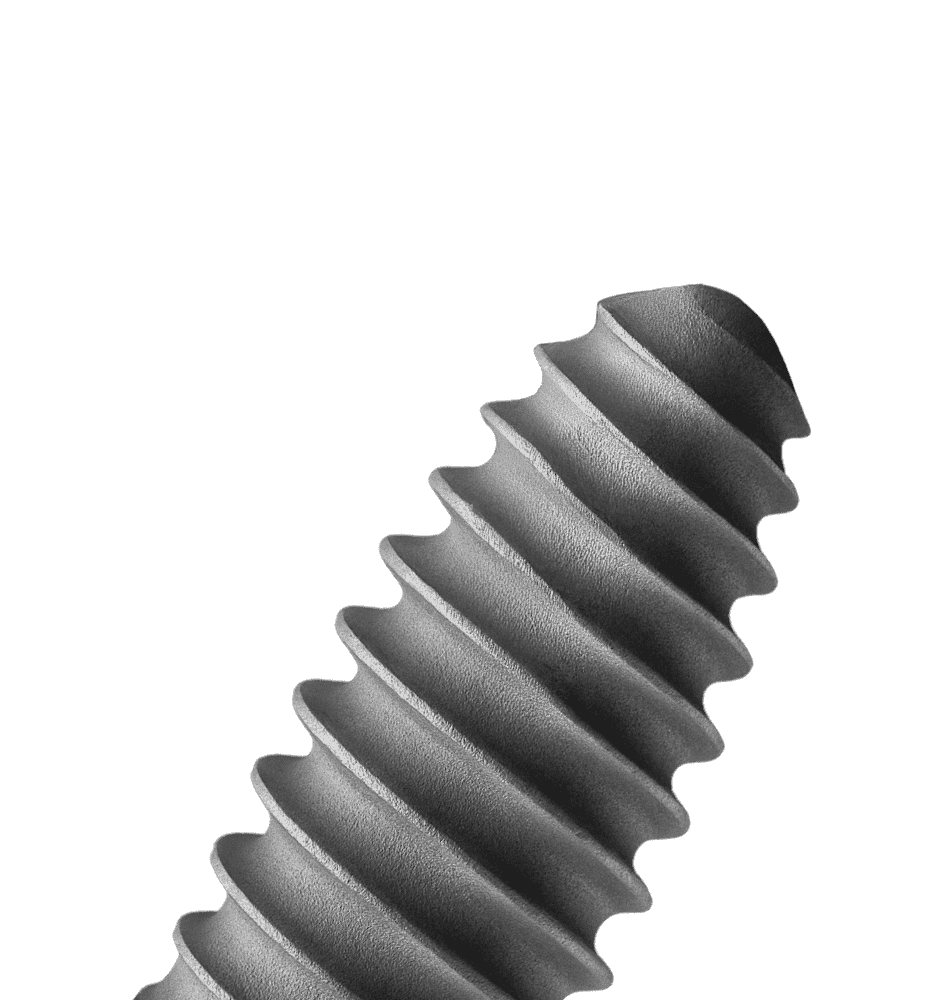

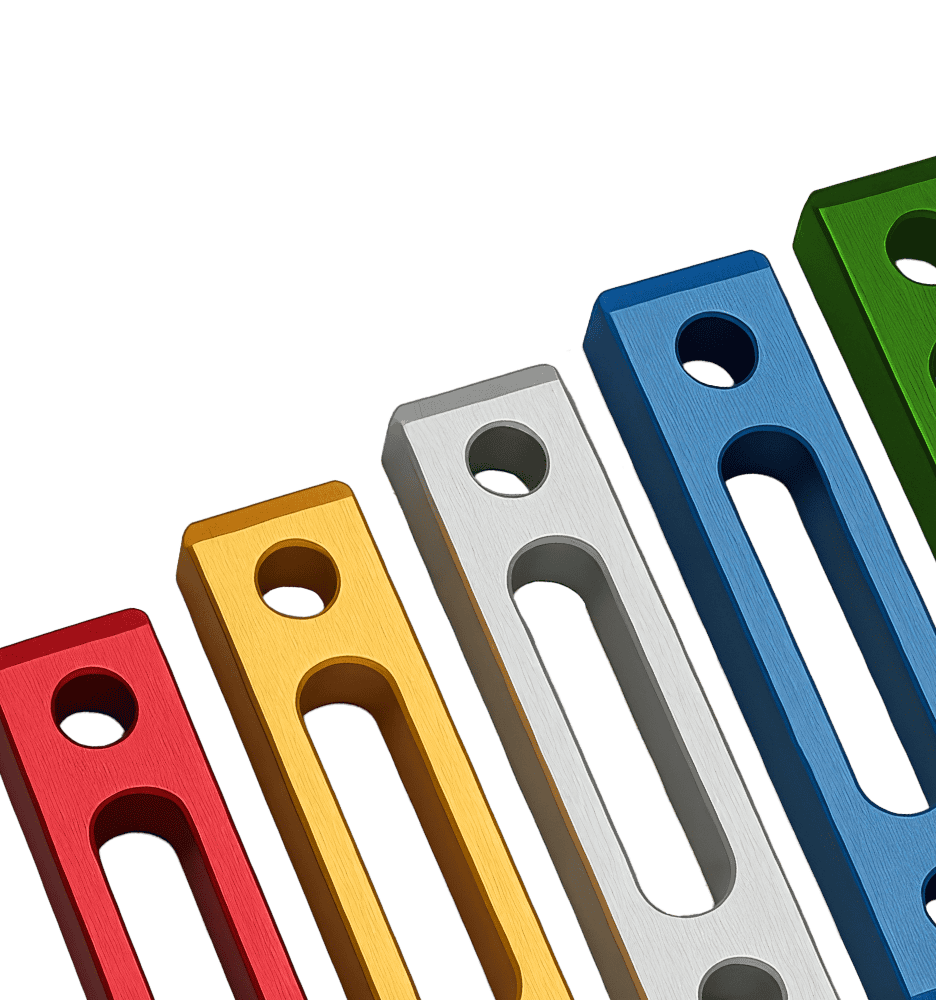

Craft expertise since 1996 alongside

industrial processes certified

in special treatments on titanium,

aluminium, steel and carbon.

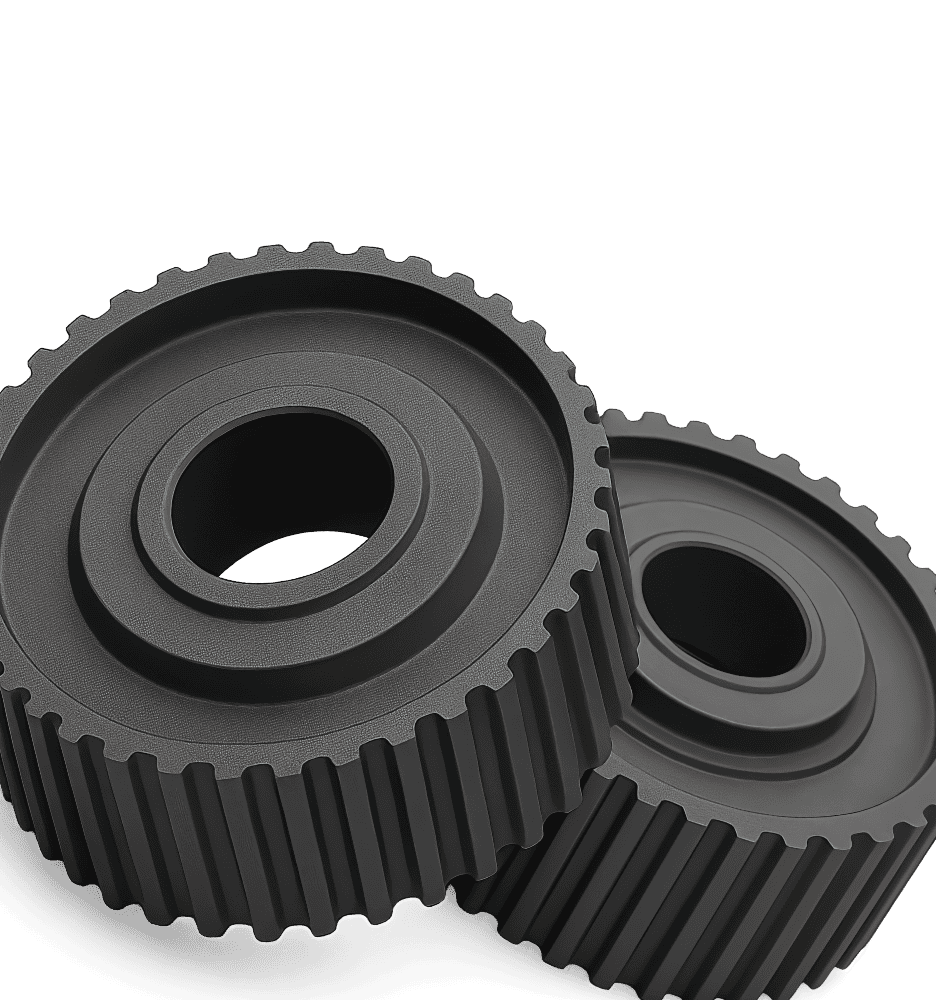

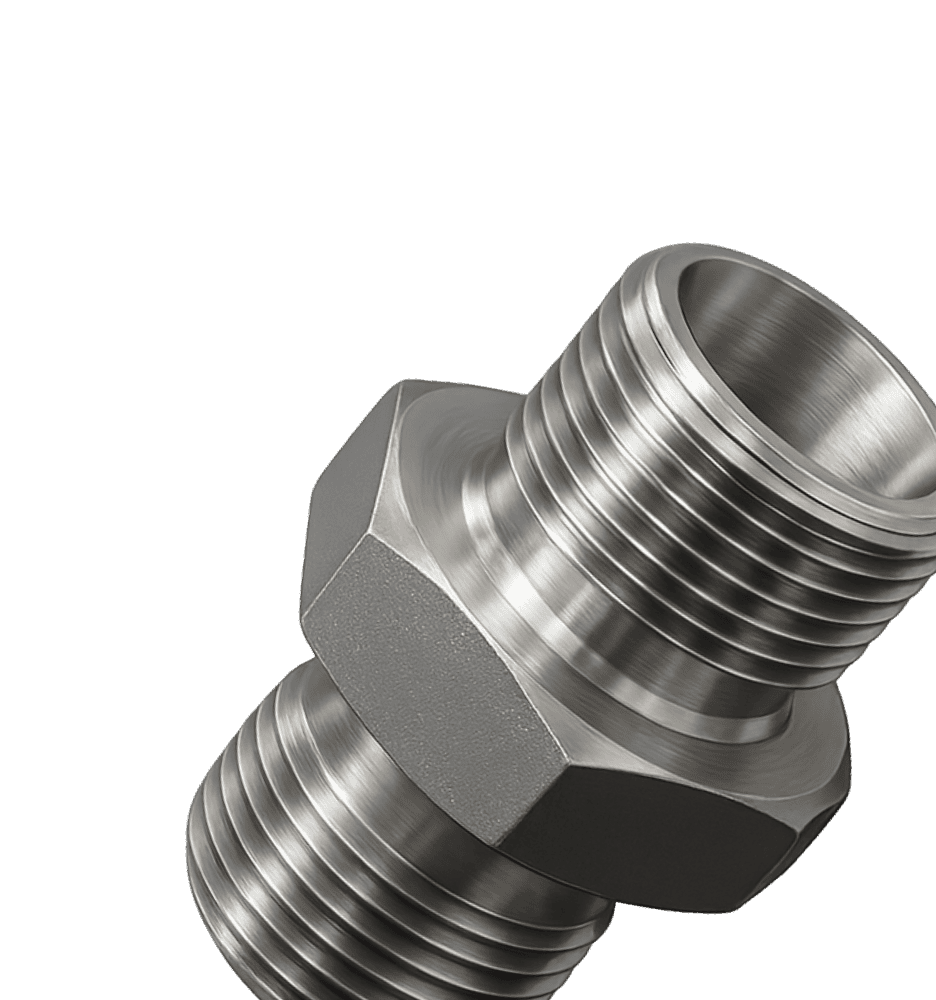

Not just treatments

Through its research and development laboratory, Alticolor researches and creates innovative solutions to produce components that attain new levels of performance and aesthetics.

Alticolor services

Certified

Excellence

Alticolor invests in excellence and continually works to provide its customers with processes that are certified in line with the highest quality standards.

ISO 9001:2015

EN 9100:2018

13485:2021

45001:2023

14001:2015

Chemical

processing

NADCAP

Accreditation

LICENCE N° 768

LICENCE N° 768